Electric Automatic Temperature Controlled Heating Cable Heat Tracing Cable

At present, most power plants still use mineral coal as the main fuel. Using such fuel will produce a large amount of su

Basic Info.

| Model NO. | LSR, MSR, HSR, DHC, PHC, etc. |

| HS Code | 8516800000 |

| Production Capacity | 100000 M/Month |

Product Description

At present, most power plants still use mineral coal as the main fuel. Using such fuel will produce a large amount of sulfur dioxide, which will be discharged into the air, causing great environmental pollution. Although the domestic environmental pollution is great, the country is also gradually eliminating high pollution enterprises. However, if large-scale power plants are eliminated at one time, it will seriously affect people's lives, and it is not a good way to take. These highly polluting thermal power plants can only use the traditional wet desulfurization method to reduce the environmental pollution.

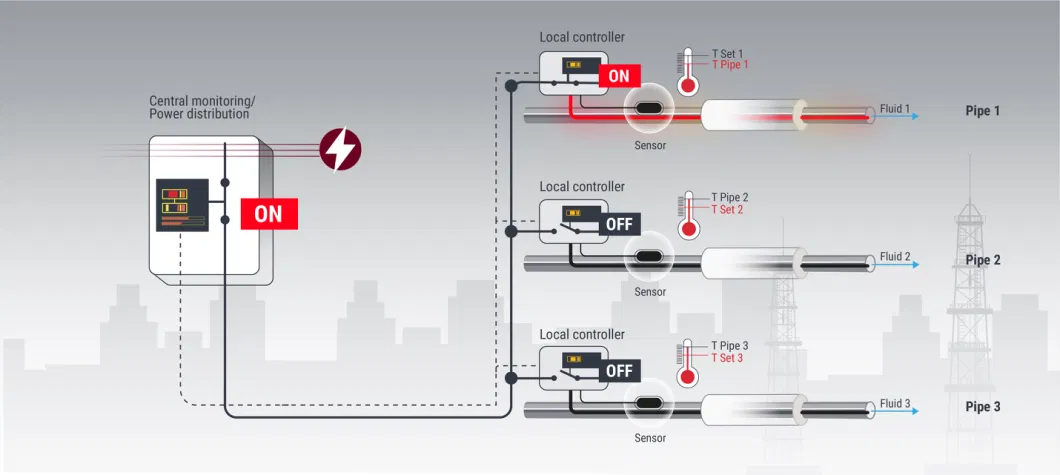

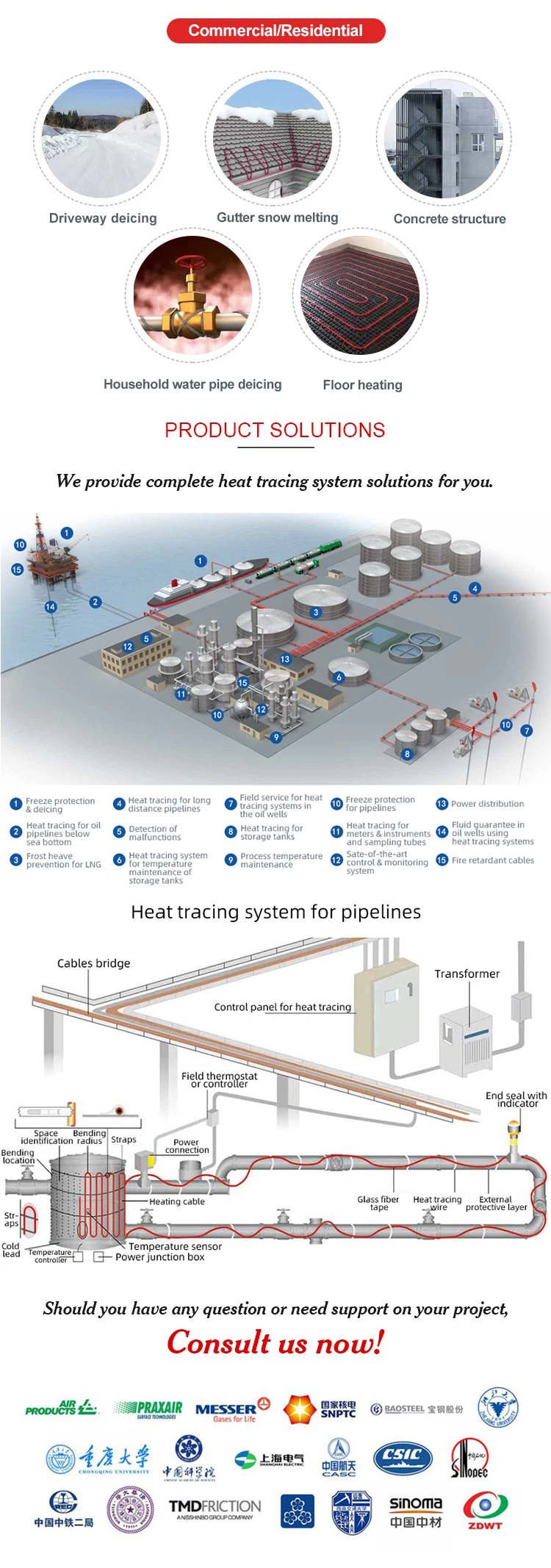

The wet desulfurization method is composed of various slurry pipelines and process water pipelines. When the ambient temperature is low in winter, the slurry pipelines and process water pipelines are easy to freeze and block, which reduces the desulfurization efficiency and even causes the equipment to fail to operate normally. Early installation of steam on these slurry pipelines and process water pipeline walls can solve the problem of freezing and blocking in winter. Although it can solve the problem of freezing and blocking, new problems have arisen, The heat dissipation speed of steam from the steam source to the terminal point is fast, the amount of investment in pipeline installation is large, and it is easy to leak. So the current new generation of heat tracing mode - electric heat tracing has become the first choice. The advantages of using electric tracing band as the heat tracing method are as follows:1. The electric tracing ribbon is flat and can be closely attached to the pipe wall, which is conducive to heat transfer.2. The electric tape is soft, easy to install, and can be used in any length.3. The electric tracing band heats evenly, which can effectively maintain the constant temperature of the pipe wall, so that the pipe will not be frozen at any time.

Send to us